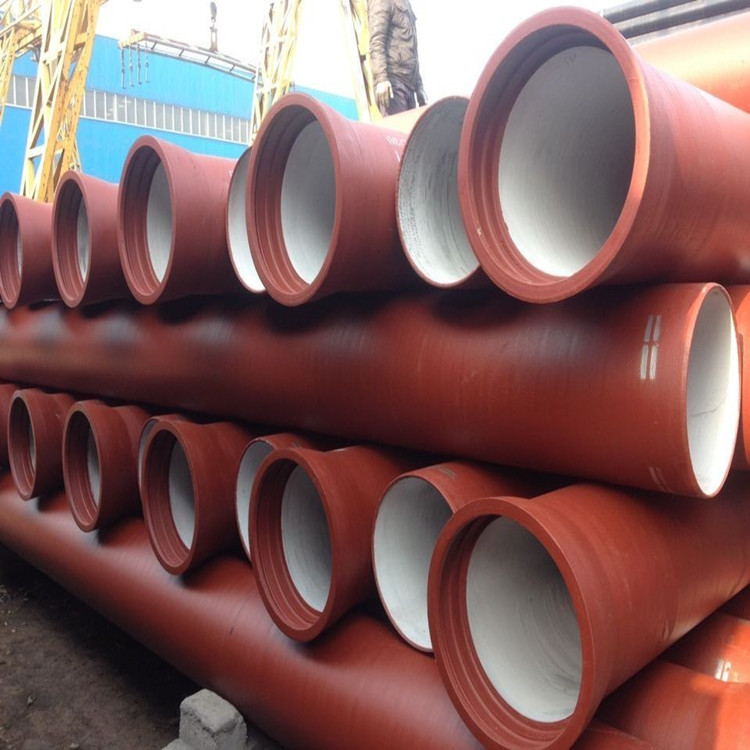

Ductile Iron Pipe

Company Name: Shandong Hongtai Metal Products Co.,Ltd.

Tel: +86-13606359804

whatsapp: +86 13606359804

E-mail :hongtai@sdhtmetalgroup.com

The material of the ductile iron pipe is solid iron. Because the mechanical residences of popular solid iron aren't excessive, measures are taken to transform flake graphite in cast iron into round graphite, which greatly improves the mechanical homes,as a way to distinguish normal forged iron, it's miles called nodular cast iron.

Ductile iron pipe is a conveying pipe forged from iron with nodularizing agent. However, there are very many kinds of solid iron pipes, and ductile iron pipe is only one form of solid iron pipe. The cause why the finished ductile iron pipe pool has been higher stepped forward is the mechanical nature of the cloth itself. The character of iron and the performance of steel are properly meditated in ductile iron pipe, so ductile iron pipe has the title of "metallic in preference to iron".

Limit deviations on length(mm)

Socket and spigot pipes (full length or shortened): -30/ + 70

Fittings for socketed joints:土20

Pipes and fittings for flanged joints:土10*

Lead time:7 to 25 working days after the receipt of 30% deposit

Payment terms:30%TT for deposit, 70% balance before shipment or LC at sight

Packing:Wooden pallet or according to customer's request

Ductile cast iron pipe (DCIP): which include annealed ductile iron pipe (currently suitable for small and medium diameter pipes), as-solid ductile iron pipe (presently suitable for small and medium diameter pipes).

Ductile iron pipe is the manufactured from modern city water supply, property fire safety, and fuel transportation. But, many customers do no longer recognize its advantages and drawbacks. Nowadays i can let you know the significance of galvanizing for ductile iron pipe. After investing big sums of money and repeated exams on endless substances for many years, we subsequently located a cheap and tremendous anti-corrosion material that may be implemented to standard conditions—zinc. The pipeline performs an lively protecting position and forms a solid protecting layer. At some stage in the touch manner with the soil, the metal zinc regularly transforms into a tight, cohesive, non-stop zinc salt layer, and the outer layer of asphalt paint (seals the pores) is as like skinny movies, zinc is transformed into insoluble zinc salts in place of soluble zinc hydroxides. One of the main functions of the sprayed zinc layer is the capability to robotically restore the protecting layer on the broken website. On the way to resolve the corrosion hassle of ductile iron pipes to hold the integrity of the protective layer, zinc ions migrate to the damaged website through sealing the pores (ie bituminous paint coating) to fill the wound and rework right into a stable insoluble spray.

The anticorrosion remedy of ductile iron pipes additionally has the following factors: first, asphalt paint coating, asphalt paint coating is used to transport gasoline pipelines. Preheating the pipe earlier than portray can enhance the adhesion of asphalt paint and accelerate drying. The second kind is cement mortar lining special coating. This inner anti-corrosion degree is suitable for pipelines that transport sewage and can improve the corrosion resistance of the lining. The third kind is epoxy coal tar pitch coating, that is appropriate for both fuel pipelines and sewage pipelines. It is a -component coating, which has excessive adhesion and a very easy surface. Epoxy ceramic lining is appropriate for sewage pipes and gasoline pipes, but due to the difficulty of producing system, the value is excessive, so there are positive barriers in use. The final type, the epoxy ceramic lining has high adhesion and end and is an first-rate anti-corrosion coating. Aluminate cement coating and sulphate cement coating, these two unique cement coatings are appropriate for the inner anti-corrosion of ductile iron pipes used in sewage pipelines, and enhance the capability to face up to the erosion of acid and alkali additives in sewage.

Packing of Ductile iron pipe

Our Factory

Company Certificate

Customer Visit

FAQ

Q:Will you can accept the customized and OEM products?

A:Yes,we can do the production based on your drawings and with your logo,also because we have very strong design and development team,so the feedback is very good for customized product.

Q:What is your payment terms?

A:Commonly two payment term for new customers

1 ) 30%T/T as deposit,70% balance against B/L copy.

2)100% Irrevocable L/C at sight.

If you need other terms, please feel free to contact us too, we will try our best.

Q:How about the samples? Is it free to extra fees?

A:Samples are free, you need to pay for shipping.

Q:How long is your delivery time?

A:Our daily inventory is more than 8000 tons, so far common products size,just need 5 days from stocks; if the special size from new production, delivery 7-15 days.

Q:How to control and guarantee your shipment quality?

A:1) All our factories are ISO 9001 certified facility;

2) World famous origin mills as TISCO, Bao steel;

3) Ex factory inspection by our own laboratory;

4) SGS/BV Third party inspection before delivery.

Related News

Submitted successfully

We will contact you as soon as possible